Inverter, Direct Drive, or Belt Drive: Which Washer Motor Lasts Longest?

Washing machines have evolved dramatically over the last decade, with manufacturers introducing new motor technologies to improve efficiency, performance, and reliability. If you’re shopping for a new washer—or troubleshooting issues with your current one—understanding how each motor type works can help you make informed decisions and better diagnose problems.

This guide breaks down the three major washer motor technologies—inverter motors, direct drive systems, and belt-driven setups—and compares their durability, maintenance needs, noise levels, and long-term reliability.

How Washer Motor Systems Work

At the heart of every washing machine is a motor responsible for spinning the drum, agitating clothes, and completing different wash cycles. The way that the motor connects to the drum determines:

- Noise and vibration levels

- Energy efficiency

- Longevity

- Cost of repairs

- Overall performance

Modern washers fall into one of the following categories:

- Inverter Motor Washers

- Direct Drive Motor Washers

- Belt Drive Motor Washers

Let’s examine each one.

1. Inverter Motor Technology

What It Is

An "inverter motor" refers to a motor controlled by inverter technology, which adjusts speed electronically instead of switching on and off abruptly. Many inverter motors are brushless, making them more durable than older brushed motors.

Key Advantages

- Highly energy-efficient due to precise speed control

- Quiet operation

- Less heat generation

- Reduced wear (because of smooth acceleration)

Durability Rating

High (8.5/10).

Because these motors experience less stress and fewer mechanical shocks, they tend to last longer than traditional belt drive designs.

Typical Issues

- Faulty control boards (not the motor itself)

- Sensor failures

- Complex diagnostics requiring technical knowledge

Best For

Users prioritize energy savings, low noise, and long-term reliability.

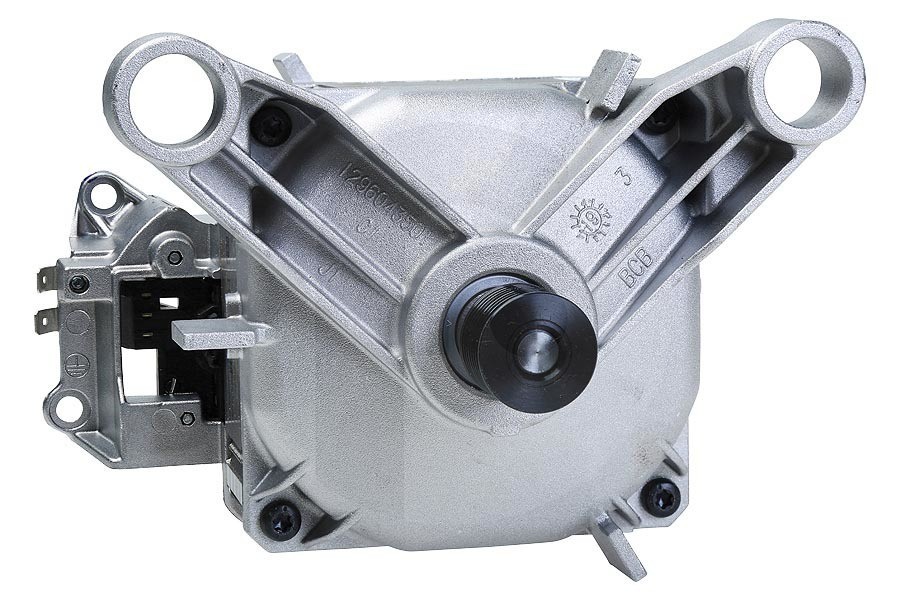

2. Direct Drive Motor Technology

What It Is

Direct drive washers connect the motor directly to the drum, eliminating belts and pulleys. This design reduces mechanical components, which naturally enhances durability.

Direct drive motors are commonly found in newer high-efficiency top-loaders and many front-load washers.

Key Advantages

- Very few moving parts

- Extremely quiet operation

- Excellent stability during high-speed spins

- Lower long-term maintenance needs

Durability Rating

Very High (9.5/10).

With minimal mechanical wear points, direct drive systems are considered the most durable motor design currently available.

Typical Issues

- More expensive motor replacements if failure occurs

- Sometimes difficult to access due to compact designs

- Vibration if the load is unbalanced

Best For

Homeowners seeking maximum longevity, low vibration, and fewer mechanical breakdowns.

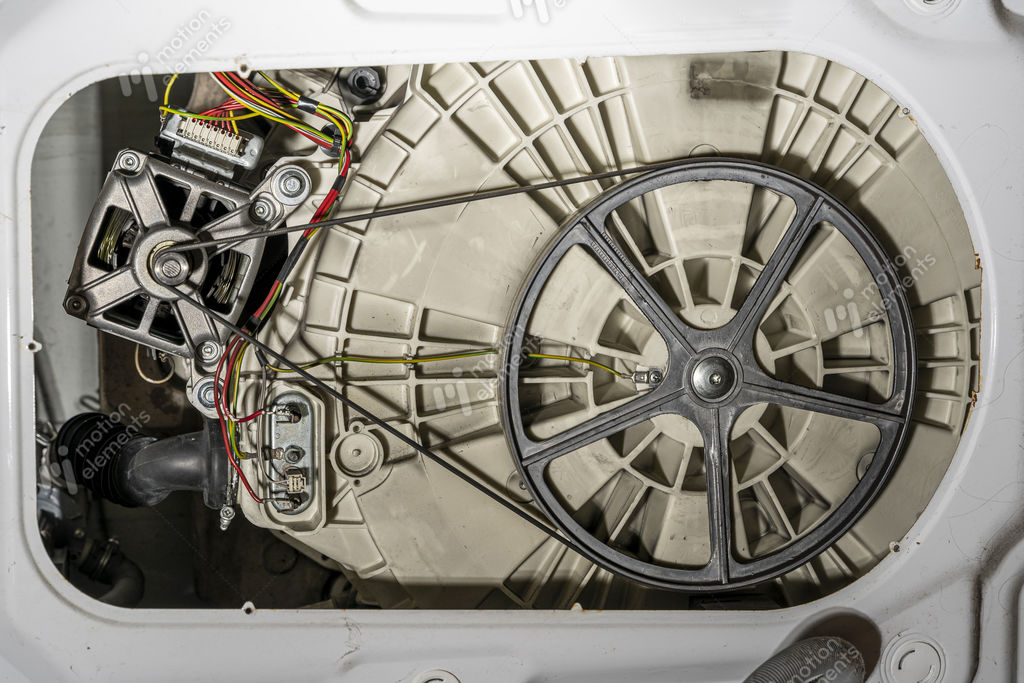

3. Belt Drive Motor Technology

What It Is

This traditional system uses a belt and pulley to transfer motor power to the washer drum. While older, belt drives remain common in budget-friendly models.

Key Advantages

- Lower purchase price

- Simpler DIY repairs

- Replacement parts (belts, pulleys) are inexpensive

Durability Rating

Moderate (6.5/10).

These systems wear out faster than direct or inverter motors because the belt and pulley components degrade over time.

Typical Issues

- Slipping or broken belts

- Noisy operation

- Vibrations at high spin speeds

- Worn pulleys or bearings

Best For

Budget-conscious users or those who prefer appliances that are easy to service at home.

Which Washer Motor Type Is the Most Durable?

Winner: Direct Drive Motors

Direct drive systems lead in durability due to their simplified mechanical structure. Internal research and user experiences consistently show:

| Motor Type | Mechanical Parts | Durability | Noise Level | Maintenance Cost |

|---|---|---|---|---|

| Direct Drive | Very Few | ★★★★★ | Very Quiet | Medium |

| Inverter Motor | Few | ★★★★☆ | Quiet | Medium-High |

| Belt Drive | Many | ★★★☆☆ | Noisy | Low |

Durability Ranking Summary

- Direct Drive – Best Overall Longevity

- Inverter Motor – High Efficiency & Great Reliability

- Belt Drive – Good for Budget Buyers but Higher Wear

Troubleshooting Tips for Each Motor Type

Direct Drive Problems

- Washer not spinning → check motor coupling or hall sensor

- Excess vibration → unbalanced loads or suspension rods

Inverter Motor Problems

- Machine not starting → inverter PCB may be faulty

- Random speed changes → check motor sensors and wiring

Belt Drive Problems

- Drum won’t spin → belt may be loose or broken

- Burning smell → worn belt rubbing against the pulley

For more appliance care, troubleshooting help, and expert guides, visit Appliance Rescue — a resource dedicated to practical advice rather than repair services.

If you need more detailed troubleshooting support or want to ask a question, you can also Contact us directly.

Final Thoughts

Washer motor technology has made significant advancements, but the best choice depends on what you value most. Direct drive washers offer unmatched durability, inverter motors provide energy-efficient sophistication, and belt drive machines remain cost-effective and easy to repair.

Understanding these differences ensures smarter buying decisions, better troubleshooting, and longer-lasting home appliances.